GCAN-PLC-400

GCAN-PLC-510

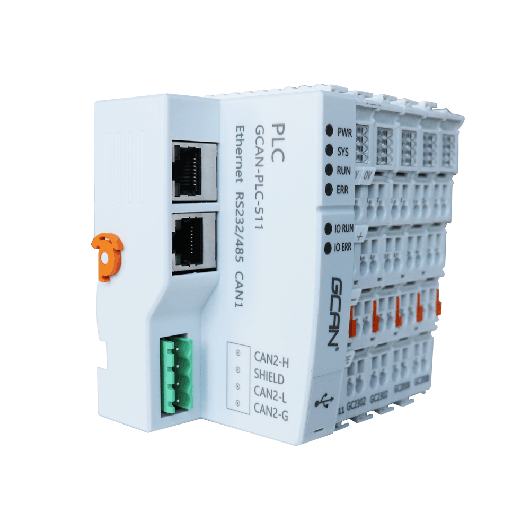

GCAN-PLC-511

GCAN-PLC-400/510/511

With CANBUS Communication.

The GCAN-PLC module consists of a programmable control module (GCAN-PLC-400/510/511) and several I/O modules (GC-1008/2008/…). The control module has a variety of fieldbus communication interfaces that allow users to connect to the network and communicate with other devices.

Selection table

| GCAN-PLC-400 | GCAN-PLC-510 | GCAN-PLC-511 | GCAN-PLC-301 | GCAN-PLC-302 | GCAN-PLC-320 | GCAN-PLC-321 | GCAN-PLC-322 | |

| Number of CAN ports | 1 | 1 | 2 | 0 | 1 | 0 | 1 | 2 |

| Number of Ethernet ports | 1 | 1 | 1 | 0 | 0 | 2 | 2 | 2 |

| Number of RS232 ports | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Number of RS485 ports | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| CANopen communication | support | support | support | × | support | × | support | support |

| MODBUS communication | support | support | support | support | support | support | support | support |

| programming software | codesys or OpenPCs | |||||||

| programming language | Sequential function chart, ladder diagram, structured text, function block diagram, instruction list | |||||||

| Install Way | DIN rail installation | |||||||

| Rated Power Supply | 24V DC | |||||||

| Scalable IO number of modules | Maximum 32 tablets | Maximum 32 tablets | Maximum 32 tablets | Maximum 16 tablets | Maximum 16 tablets | Maximum 16 tablets | Maximum 16 tablets | Maximum 16 tablets |

| Expandable to IO interfaces | Maximum 512 | Maximum 512 | Maximum 512 | Maximum 256 | Maximum 256 | Maximum 256 | Maximum 256 | Maximum 256 |

| Processor frequency | 200M | 400M | 400M | 180M | 180M | 200M | 200M | 200M |

| Protection level | IP20 | |||||||

| Operating temperature | -40°C~+85°C | |||||||

| EMC anti-interference level | Zone B | |||||||

Technical Advantages

| Model | Characteristic | Communication Bus | ||

| CPU Frequency | Program Storage | Data Storage | ||

| GCAN-PLC-400 | 168M | 16M | 512K | 1*CAN+1*Ethernet+1*RS232 (oder RS485) |

| GCAN-PLC-510 | 400M | 32m | 16M | 1*CAN+1*Ethernet+1*RS232 (oder RS485) |

| GCNA-PLC-511 | 400M | 32m | 16M | 2*CAN+1*Ethernet+1*RS232+1*RS485 |

1. Comes with common communication interfaces such as CAN interface, Ethernet port, RS232/485, etc.

Users can program it arbitrarily to achieve bus communication and networking, and support common communication protocols such as: CANopen, ModbusRTU, ModbusTCP, etc.

2. Using 10 plug-in expansion methods, the number of I0 can be flexibly expanded at will

The GCAN-PLC series can expand the number of IO according to the actual needs of the user. The maximum scalability supports 256 IO points and the user can freely choose the type of IO such as: analog, digital, counter, PT100, etc. The GCAN-PLC series is very easy to expand. Users only need to insert the corresponding functional modules to achieve it. The module itself is very small in size. Users can expand rich functions in a compact space and flexibly respond to various industrial site needs.

IO Selection table

| I/O | Type | Characteristic | Signal | Channel |

| Digital input | GC-1008 | Digital input (PNP) | 24V DC | 8-channel |

| GC-1018 | Digital input (NPN) | 24V DC | 8-channel | |

| GC-1502 | Counter(200kHz max) | – | 2-channel | |

| Digital output | GC-2008 | Digital output (PNP) | 24V DC | 8-channel |

| GC-2018 | Digital output (NPN) | 24V DC | 8-channel | |

| GC-2204 | Relay output | – | 4-channel | |

| GC-2302 | PWM (20Hz~200kHz) | – | 2-channel | |

| Analog input | GC-3604 | Voltage input, 16 bits | -5~+5V | 4-channel |

| GC-3624 | Voltage input, 16 bits | -10V~+10V | 4-channel | |

| GC-3644 | Current input, 16 bits | 0-20mA | 4-channel | |

| GC-3654 | Current input, 16 bits | 4-20mA | 4-channel | |

| GC-3664 | Voltage input, 16 bits | 0~+5V | 4-channel | |

| GC-3674 | Voltage input, 16 bits | 0~+10V | 4-channel | |

| GC-3804 | 2-wire PT100, 16 bits | Thermal resistance | 4-channel | |

| GC-3814 | 2-wire PT1000, 16 bits | Thermal resistance | 4-channel | |

| GC-3822 | 3-wire PT100, 16 bits | Thermal resistance | 2-channel | |

| GC-3832 | 3-wire PT1000, 16 bits | Thermal resistance | 2-channel | |

| GC-3844 | K type thermocouple | Thermocouple | 4-channel | |

| GC-3854 | S type thermocouple | Thermocouple | 4-channel | |

| GC-3864 | T type thermocouple | Thermocouple | 4-channel | |

| GC-3874 | J type thermocouple | Thermocouple | 4-channel | |

| Analog output | GC-4602 | Voltage output, 16 bits | -5V~+5V | 2-channel |

| GC-4622 | Voltage output, 16 bits | -10V~+10V | 2-channel | |

| GC-4642 | Current output, 16 bits | 0-20mA | 2-channel | |

| GC-4652 | Current output, 16 bits | 4-20mA | 2-channel | |

| GC-4662 | Voltage output, 16 bits | 0~5V | 2-channel | |

| GC-4672 | Voltage output, 16 bits | 0~10V | 2-channel | |

| GC-4674 | Voltage output, 12 bits | 0~10V | 4-channel | |

| Special module | GC-6101 | RS232/RS485 extension | – | – |

| GC-6201 | GPRS extension | – | – | |

| GC-6221 | 4G extension | – | – | |

| GC-6301 | Bluetooth2.0 extension | – | – | |

| GC-6321 | Bluetooth5.0 extension | – | – | |

| GC-6401 | Zigbee extension | – | – | |

| GC-6501 | WiFi extension | – | – | |

| GC-8012 | Power extension | – | – |

3. Use five programming languages for flexible programming

The GCAN-PLC series uses the German embedded real-time (run-time) kernel system, which not only has strong real-time performance and processing capabilities, but the system also supports users to program it using 5 programming languages that comply with the IEC61131-3 standard, including : SFC (Sequential Function Chart), LD (Ladder Diagram), FBD (Function Block), ST (Structured Text), 1 L(Instruction List), flexible use of familiar programming languages can shorten the project development cycle.

GCAN-PLC can be programmed using 5 programming languages that comply with the IEC 61131-3 standard, including: SFC (Sequential Function Chart), LD (Ladder Diagram), FBD (Function Block), ST (Structured Text), IL (instruction list). A variety of standard programming languages can be used, making the PLC program highly portable and reusable. IEC 61131-3 also allows the use of multiple programming languages in the same PLC, allowing program developers to choose the most appropriate programming language for each specific task, and also allows different software modules in the same control program to use different programming language.